Aluminum vs. Copper in Distribution Transformers

Jan 13, 2026 / Views: 67 / by MiCloud

In industrial power distribution, whether transformer windings use copper or aluminum directly determines equipment stability, lifespan, and cost. Many transformers with “equivalent parameters” exhibit significantly poorer temperature rise and voltage stability in actual use—the root cause lies in winding material.

This article shares four reliable methods to distinguish copper from aluminum, while comparing material differences to help you select the right transformer.

Why Windings Material Matters in Transformers

Windings are the core component of transformers. Differences in electrical conductivity, thermal conductivity, and mechanical properties between copper and aluminum directly impact the equipment's performance. For B2B procurement, selecting the right material is key to balancing cost and risk.

Cabinet Thermal Margin: Copper windings operate at lower temperatures for the same volume. While aluminum windings can meet requirements with proper sizing, they impact distribution cabinet derating design and increase costs for fans and filters.

Installation Space Constraints: Copper windings enable smaller physical dimensions, whereas aluminum windings require larger conductor cross-sections, directly affecting cabinet layout.

Terminal Reliability: Copper windings facilitate easier terminal handling, while aluminum windings demand more precise wiring techniques. Failure to meet standards increases on-site construction quality risks and post-installation warranty claims.

Cost Considerations: Aluminum windings offer lower raw material costs, providing a clear advantage in initial procurement expenses. Though copper windings carry a higher unit price, they ensure more consistent supplier quality, reducing the effort required for supplier vetting.

Four Methods to Identify Whether Transformer Windings Are Copper or Aluminum

Numerous techniques for distinguishing copper and aluminum windings circulate online, but most lack practicality and may even be misleading. The following 4 methods, proven through practice, can help you accurately determine the winding material.

Observe the Color of the Transformer Winding Cross-Section

This is the most intuitive identification method. Copper has a natural purple-red or yellow color, while aluminum appears silver-white. Use a small knife to carefully score a small opening in the insulation layer of the winding. Observe the color of the internal conductor: yellow or reddish-purple indicates copper windings, while silver-white indicates aluminum windings. Note that some manufacturers may apply a copper coating to aluminum windings to mislead. In such cases, score multiple points to verify and avoid being deceived by the surface coating.

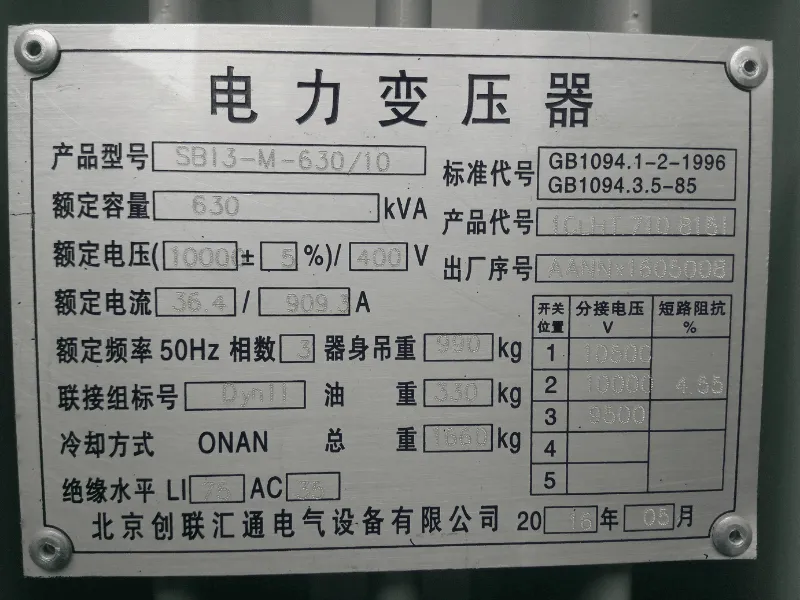

Check the Transformer Nameplate

Reputable manufacturers clearly label the winding material on their transformer nameplates. Copper is universally marked as “Cu,” while aluminum is denoted as “Al.” During procurement, directly inspect the nameplate. If the marking is unclear or absent, request material certification documents from the manufacturer to avoid purchasing counterfeit products where aluminum is passed off as copper.

Compare Weights of Identical Specifications

Copper has a density of approximately 8.96 g/cm³, while aluminum is about 2.7 g/cm³. Transformers with copper windings will be noticeably heavier for the same specifications, typically around 20% heavier than aluminum-wound counterparts. For small control transformers, direct weight comparison using an electronic scale is feasible. For large distribution transformers, refer to the manufacturer's weight specifications—significant weight discrepancies for products of the same capacity likely indicate material differences.

Observe the Conductor Cross-sectional area of the Windings

Aluminum has approximately 60% of copper's electrical conductivity. To achieve equivalent electrical performance, aluminum windings require a larger conductor cross-sectional area. When disassembling or examining cross-sectional diagrams, aluminum windings will typically feature thicker wires than copper windings. However, note that some manufacturers optimize winding structures to reduce this difference. Therefore, this method is recommended for use in conjunction with other verification techniques.

Differences Between Copper and Aluminum Windings in Distribution Transformers

Material selection for distribution transformers is critical. While many believe “copper windings are inherently superior to aluminum ones,” the reality requires context-specific analysis.

Efficiency

According to the latest DOE (U.S. Department of Energy) efficiency standards, both copper and aluminum winding distribution transformers can achieve identical efficiency metrics. Although aluminum has lower electrical conductivity than copper, manufacturers can compensate by increasing the conductor cross-sectional area. Ultimately, the energy losses in transformers made from both materials are nearly identical. Therefore, the claim that “copper windings are more efficient” is not absolute.

Cost

In terms of raw material prices, copper is significantly more expensive than aluminum. This directly results in copper-wound transformers costing 50%-100% more to procure than aluminum-wound ones. However, note that copper windings have lower long-term maintenance costs, while aluminum windings demand higher installation precision. Improper installation can increase future failure costs.

Size and Weight

Copper windings require smaller conductor cross-sectional areas, theoretically allowing for smaller transformer dimensions. In practice, most manufacturers use standardized enclosures, resulting in minimal size differences between copper and aluminum windings of the same model—typically only a few inches.

In terms of weight, copper-wound transformers are approximately 20% heavier than aluminum-wound ones. This difference is particularly critical for rooftop or platform installations—copper-wound transformers increase structural engineering costs, while aluminum-wound units are better suited for load-bearing-sensitive scenarios.

Manufacturing and Oxidation Resistance

From a manufacturing perspective, aluminum offers superior ductility, easier machining, and better adhesion for thermosetting insulation coatings between windings. Aluminum welding is also simpler, whereas copper requires higher welding temperatures and typically employs brazing techniques, which may slightly degrade electrical conductivity at joints.

Regarding oxidation resistance, both copper and aluminum oxidize, but the outcomes differ. Copper oxidation produces porous verdigris that degrades conductivity, while aluminum oxidation forms a dense protective layer that prevents further corrosion.

However, within transformers, this issue is mitigated by manufacturing techniques. Aluminum winding joints use inert gas welding, where the oxide layer acts as a protective coating. In sealed oil-immersed transformers, joints are submerged in insulating oil, eliminating oxidation concerns entirely.

Service Life

Transformer lifespan is primarily determined by the insulation system, not the winding material. In commercial and industrial applications, there is no conclusive evidence that copper-wound transformers last longer than aluminum-wound ones. When properly selected and installed according to specifications, transformers made from either material can achieve their designed service life.

When to Choose Copper or Aluminum Transformer Windings

There is no absolute superiority between copper and aluminum windings—only suitability for specific scenarios. Below are reference applications for both materials to help you make precise selections.

Copper Windings are Suitable for these Scenarios

Critical operational environments: Hospitals, data centers, precision manufacturing plants, and other locations demanding extremely high power supply reliability. Copper windings' stability prevents major losses caused by equipment failures.

Harsh operating environments: Scenarios involving frequent overloads, high ambient temperatures, vibration, or mechanical stress. Copper's mechanical strength and thermal conductivity better withstand demanding conditions.

Customized compact installations: Projects with strict cabinet size constraints. Copper windings' smaller footprint simplifies layout design.

Aluminum Windings are Suitable for these Scenarios

Budget-Sensitive Projects: For non-critical applications with stable loads and strict initial procurement cost requirements, aluminum windings can significantly reduce procurement budgets.

Weight-Constrained Scenarios: In projects with load-bearing requirements, such as rooftop installations or mobile substations, the lightweight advantage of aluminum windings is more pronounced.

Standard Load Applications: For stable load scenarios like commercial building power distribution or standard industrial production lines, aluminum windings fully meet operational needs.

Get in Touch With CLHT POWER Transformers

Find expert guidance on choosing a transformer type that's right for you by reaching out to CLHT POWER online or at +8613949094161, and feel free to request a quote if you already know what you need.