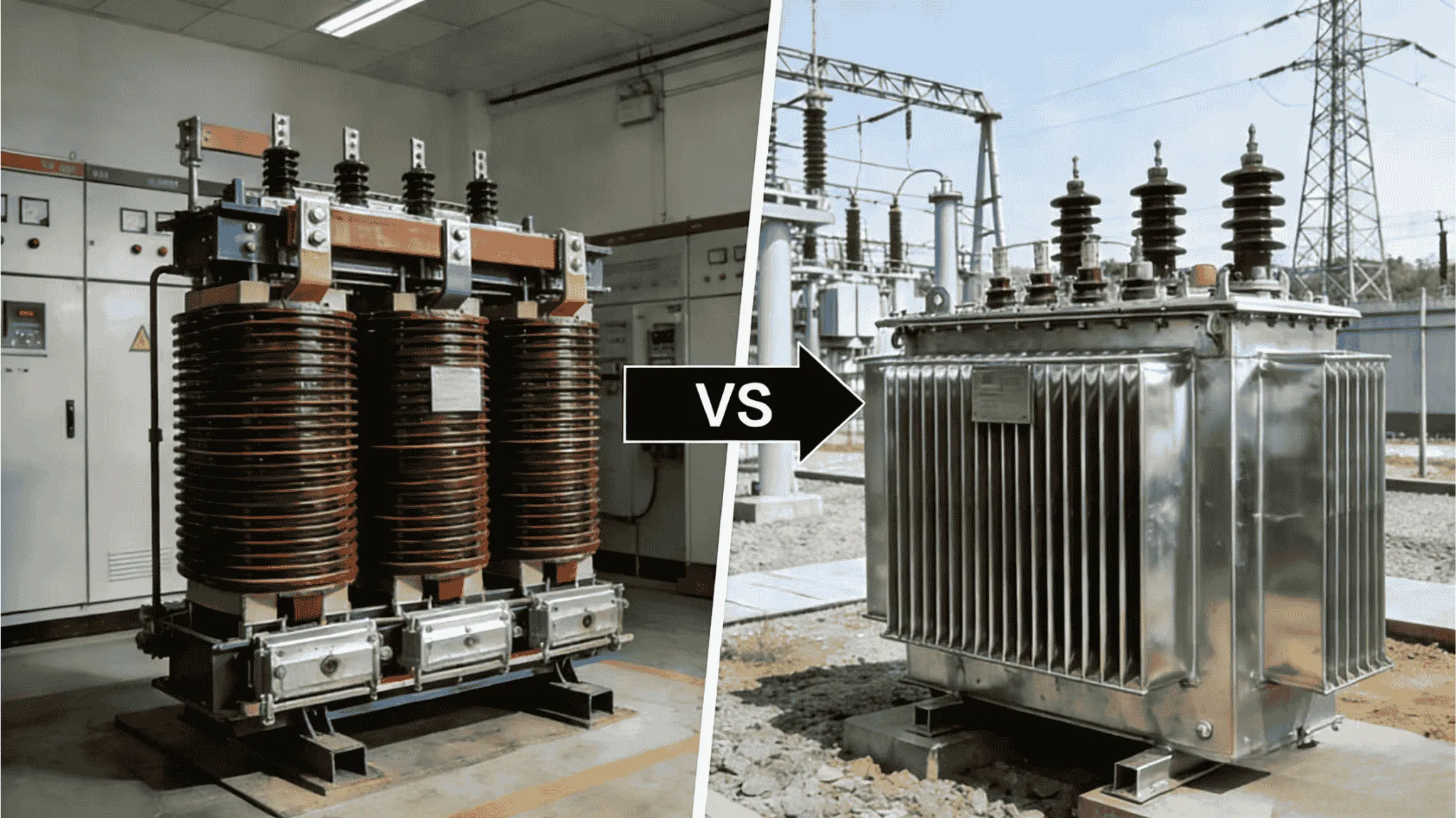

Dry-Types VS Oil-Filled Transformer

Jan 12, 2026 / Views: 42 / by MiCloud

Introduction

Transformers serve as core equipment in power transmission and distribution systems, where their performance stability and adaptability directly impact the safe operation of power grids and energy utilization efficiency. Among the various transformer types, dry-type transformers and oil-filled transformers represent the two most widely applied categories.

This article comprehensively dissects the characteristics of dry-type and oil-filled transformers across four dimensions: fundamental understanding, core differences, pros and cons analysis, and selection guidelines. It aims to help readers clarify the distinctions between the two and precisely match their specific application requirements.

What is a Dry-Type Transformer

A dry-type transformer is a stationary electrical device that does not require insulating liquid. Its core feature is the use of an environmentally friendly temperature insulation system, hence it is also known as a “Cast Resin Type Transformer.”

Structurally, dry-type transformers feature a casing with adequate ventilation. Their internal windings are made of varnish-coated copper or aluminum, relying on air within the equipment for thermal dissipation and cooling. Due to cooling limitations, the maximum operating voltage for dry-type transformers is restricted to 35kV or below.

Types of Dry-Type Transformers

Vacuum Pressure Impregnated Transformers (VPI Transformers): Enhance winding insulation through vacuum pressure impregnation, suitable for medium-to-low voltage industrial applications;

Vacuum Pressure Encapsulated Transformers (VPE Transformers): Employ vacuum pressure encapsulation technology for higher insulation reliability, ideal for harsh environments;

Open Wound Transformers: Open-wound design facilitates efficient heat dissipation, commonly used in small commercial applications;

Cast Coil Transformers: Coils are resin-encapsulated for superior insulation, offering resistance to moisture and dust.

What is an Oil-Immersed Transformer

An oil-immersed transformer, also known as an oil-filled transformer, is a voltage conversion device that uses insulating oil as its cooling medium. Its core structure involves mounting the transformer body within a welded steel tank filled with insulating oil.

During operation, heat generated by the windings and core is first transferred to the insulating oil, then conducted to external cooling media to dissipate heat. Due to the flammable nature of insulating oil, oil-immersed transformers are primarily suited for outdoor installations.

Types of Oil-Immersed Transformers

Based on phase configuration, oil-immersed transformers are primarily categorized into two types:

Single-Phase Transformers: Featuring simple construction and compact size, these are suitable for small-scale applications powered by single-phase electricity, such as households and small commercial establishments.

Three-Phase Transformers: Offering high power supply efficiency and strong stability, these are the mainstream choice for industrial production, large-scale buildings, and power transmission and distribution systems.

Dry-Type VS Oil-immersed Transformers

Insulation Materials and Product Aliases

The core insulation materials for dry-type transformers are solid substances like epoxy resin and polyester resin. These materials offer stable insulation properties and are environmentally friendly, leading to common alternative names such as cast resin transformers or epoxy resin transformers.

Oil-immersed transformers, however, utilize insulating oil (dielectric oil) as the insulating medium. This oil serves dual functions of insulation and heat dissipation. Their alternative name, oil-immersed transformers, directly reflects this core structural characteristic of being “oil-immersed.”

Cooling Medium and Heat Dissipation Efficiency

Dry-type transformers utilize air as their sole cooling medium. Air circulation is achieved through ventilation structures in the equipment housing, dissipating heat generated by the windings and core during operation. This cooling structure is simple but its efficiency is significantly influenced by ambient ventilation conditions.

Oil-immersed transformers employ a “oil + air” composite cooling mode. Operational heat is first transferred to the insulating oil. The heated oil rises to the top of the tank, where it exchanges heat with the surrounding air. After cooling, it flows back down to circulate. This cooling efficiency is significantly higher than air cooling.

Maintenance Requirements and Cost Structure

Dry-type transformers' solid insulation materials exhibit high stability. Routine maintenance involves only periodic cleaning of ventilation ports and inspection of winding insulation condition, eliminating the need for medium testing or replacement. This results in low maintenance frequency and controllable costs, though initial procurement costs are higher.

Oil-immersed transformers focus maintenance on insulating oil, requiring periodic sampling for oil quality testing, oil filtration, or oil replacement. Additionally, tank sealing integrity and cooling systems must be inspected, resulting in higher long-term maintenance costs. Conversely, their initial procurement costs are relatively lower.

Safety Risk Level Differences

The solid insulating materials used in dry-type transformers are non-combustible and self-extinguishing. Even under overload or localized overheating conditions, they are unlikely to ignite or explode, posing extremely low safety risks.

The insulating oil used in oil-immersed transformers is flammable. If the tank leaks due to corrosion, impact damage, or other causes, exposure to high temperatures or open flames can easily trigger fires or explosions. Therefore, additional protective measures such as fire barriers and oil leakage collection systems are mandatory.

Application Scenario Suitability

Dry-type transformers are better suited for medium-to-low voltage (≤35kV) and indoor applications, such as shopping malls, office buildings, hospitals, and data centers—environments with stringent safety and environmental requirements and limited installation space.

Oil-immersed transformers are more appropriate for medium-to-high voltage and outdoor applications, including transmission and distribution lines, outdoor substations, and large industrial sites requiring high-power transmission and ample installation space.

Core Performance

Dry-type transformers exhibit relatively lower operational efficiency, with higher energy losses than oil-immersed units at equivalent power ratings. However, they offer advantages in lightweight construction, compact design, and minimal installation space requirements.

Oil-immersed transformers deliver higher energy conversion efficiency and lower long-term operational energy losses. Yet, their steel tanks and substantial insulating oil result in heavier weight, larger dimensions, and higher load-bearing capacity demands for installation sites.

Installation and Transportation Difficulty

Dry-type transformers contain no liquid components, eliminating leakage concerns during transport. Installation is straightforward—merely secure the equipment, connect the wiring, and ensure adequate ventilation—resulting in lower installation costs.

Oil-immersed transformers require sealed tank protection during transport to prevent insulating oil leakage. Installation necessitates constructing foundation supports and protective facilities, making the process cumbersome and installation costs higher.

Advantages and Disadvantages of Dry-Type Transformers

Advantages of Dry-type transformers

High Environmental Safety: Dry-type transformers eliminate the need for insulating oil, fundamentally preventing soil and water contamination from oil leaks or spills, aligning with green development requirements. Utilizing non-flammable, self-extinguishing solid insulation materials, they effectively mitigate combustion and explosion risks even during overloads or localized overheating, offering exceptional safety—particularly suited for densely populated indoor environments like shopping malls, hospitals, and data centers.

Flexible and Convenient Installation: No complex protective structures like oil pits or fire barriers are required. Installation only necessitates adequate ventilation for securing and wiring, significantly shortening the installation cycle and reducing upfront site modification and construction costs. This makes them highly adaptable for indoor environments with limited installation space.

Maintenance costs are manageable: The solid insulation material offers outstanding stability. Routine maintenance only requires periodic cleaning of ventilation port dust and inspection of winding insulation status. There is no need for cumbersome operations like oil quality testing, oil filtration, or oil replacement. This not only reduces maintenance workload but also lowers maintenance material consumption and downtime losses, resulting in outstanding long-term operational economics.

Disadvantages of Dry-type transformers

Lower operational efficiency: Relying solely on air for heat dissipation results in significantly lower cooling efficiency compared to oil-immersed transformers. This leads to greater energy losses under equivalent power loads. To ensure adequate cooling, the equipment must be designed larger, occupying more installation space.

Limited temperature tolerance: Solid insulating materials degrade under high temperatures, resulting in a lower maximum allowable operating temperature than oil-immersed transformers. This makes them unsuitable for high-temperature workshops, outdoor exposure, or other high-temperature, high-load scenarios, where they would experience significantly reduced service life.

Higher initial procurement costs: Solid insulating materials like epoxy resin and manufacturing processes such as vacuum casting incur higher expenses. For equivalent power ratings, dry-type transformers cost 20%-50% more than oil-immersed units at initial purchase, posing significant pressure on projects with limited short-term budgets.

Advantages and Disadvantages of Oil-Immersed Transformers

Advantages of Oil-Immersed Transformers

Superior Efficiency: Insulating oil possesses excellent heat dissipation properties, resulting in low energy losses and suitability for high-power, extended operation. Its operational efficiency offers significant advantages. Oil-immersed transformers utilize insulating oil as the cooling medium. With a thermal conductivity far exceeding that of air, the oil rapidly dissipates heat generated by the windings and core during operation, effectively reducing energy losses such as copper and iron losses. Their operational efficiency typically exceeds 98%, enabling substantial electricity savings in high-power, continuous-duty applications and delivering outstanding long-term energy cost efficiency.

High Temperature Resistance: Operates stably in high-temperature environments, suitable for complex outdoor settings.

Cost-Effective: Low initial procurement cost with clear cost advantages in high-power applications.

Low Noise: Insulating oil dampens noise, resulting in lower operational noise levels than dry-type transformers.

Easy Recycling: Core components and insulating oil can be professionally recycled at end-of-life.

Disadvantages of Oil-Immersed Transformers

Significant Safety Risks: Insulating oil is flammable; tank damage leading to oil leakage can cause fires or explosions. The risk of safety hazards is relatively high. The insulating oil used in oil-immersed transformers is a flammable liquid with a low flash point. If the tank is damaged due to corrosion, impact, or aging, leaked insulating oil can easily ignite upon contact with high temperatures or open flames, potentially causing fires or even explosions. Such incidents not only damage equipment but also endanger personnel safety and cause environmental pollution. Significant Safety Risks: Insulating oil is highly flammable, and oil leaks from damaged tanks can easily trigger fires or explosions.

Complex Installation: Requires constructing oil pits, guardrails, and other facilities, resulting in extended installation periods and high costs.

Laborious Maintenance: Regular testing and replacement of insulating oil, along with inspections of seals and cooling systems, demand considerable time and effort.

How to Choose Dry-Type or Oil-Immersed Transformers

When selecting transformers, comprehensive evaluation is required based on application scenarios, voltage requirements, cost budgets, environmental standards, and other factors. Specific selection recommendations are as follows:

Prioritize Application Scenarios and Voltage Requirements

Voltage levels and power demands form the core basis for selection. For high-voltage, high-power applications such as transmission lines, large power plants, and industrial production lines, oil-immersed transformers are preferred. Their superior heat dissipation and voltage adaptability better meet these demands.

For medium/low-voltage, small-scale equipment applications—such as small businesses, commercial buildings, and indoor office spaces—dry-type transformers are more suitable. Their compact structure and safety/environmental features align better with these scenarios.

Balancing Efficiency and Cost (Initial Cost + Operating Cost)

From a short-term investment perspective, oil-immersed transformers have lower initial costs, making them suitable for projects with limited budgets or short-term usage. However, for long-term operation, dry-type transformers offer lower maintenance costs and reduced energy losses, providing higher overall cost-effectiveness and suitability for stable, prolonged operation.

It is recommended to conduct a full lifecycle cost analysis during selection, comprehensively considering initial procurement, installation, maintenance, energy consumption, and other expenses to void focusing solely on short-term costs while overlooking long-term losses.

Key Consideration: Installation Location

The installation location directly impacts equipment safety and operational effectiveness. For indoor settings such as shopping malls, office buildings, hospitals, data centers, and other high-traffic areas, dry-type transformers should be prioritized to eliminate the fire hazards associated with oil-immersed transformers.

If oil-filled transformers must be installed indoors, comprehensive fireproofing, explosion-proofing, and oil leakage containment systems must be installed, fully compliant with local fire safety regulations. For outdoor settings like power plants or transmission/distribution lines, oil-filled transformers are suitable, as their superior heat dissipation and noise reduction capabilities are better utilized.

Environmental and Recycling Considerations

In regions with stringent environmental regulations or a focus on low pollution and sustainable development, dry-type transformers should be prioritized. Their oil-free design eliminates environmental pollution risks.

For applications emphasizing equipment recycling, oil-immersed transformers offer advantages. Their core components and insulating oil can be professionally processed for reuse, achieving higher resource utilization rates.

Conclusion

There is no absolute superiority between dry-type transformers and oil-immersed transformers; the key lies in whether they suit specific application requirements:

For indoor, medium-to-low voltage, safety- and environmentally-conscious, and long-term stable operation scenarios, dry-type transformers are more suitable; for outdoor, medium-to-high voltage, high-power, and short-term budget-constrained scenarios, oil-immersed transformers are the better choice.

For further information on transformer selection, consult CLHT, a professional transformer manufacturer, to obtain customized selection solutions ensuring safe and efficient equipment operation.